Powered by

Nota Vision Agent (NVA)

Built for Industrial Sites—Protecting Workers, Minimizing Losses

Industrial Safety

50+ Safety Management Measures

to Prevent All Workplace Hazards

Worker Safety Management

Detection of PPE (Personal Protective

Equipment) Usage

Equipment) Usage

Apron, protective suit, safety goggles, protective gloves, hard hat,

hearing muff, dust mask, gas masks, reflective vest,

protective arm sleeves, safety harness, etc.

hearing muff, dust mask, gas masks, reflective vest,

protective arm sleeves, safety harness, etc.

Detection of Abnormal Worker Behavior

Climbing, slips, trips, falls, etc.

Detection of Worker Location and

Access to Hazardous Areas

Access to Hazardous Areas

Minimum workers below required in the area, maximum workers exceeded in the area

Workplace Safety Management

Automated Detection of Abnormal Events

Fire, smoke, steam, gas leaks, liquid leaks, spills

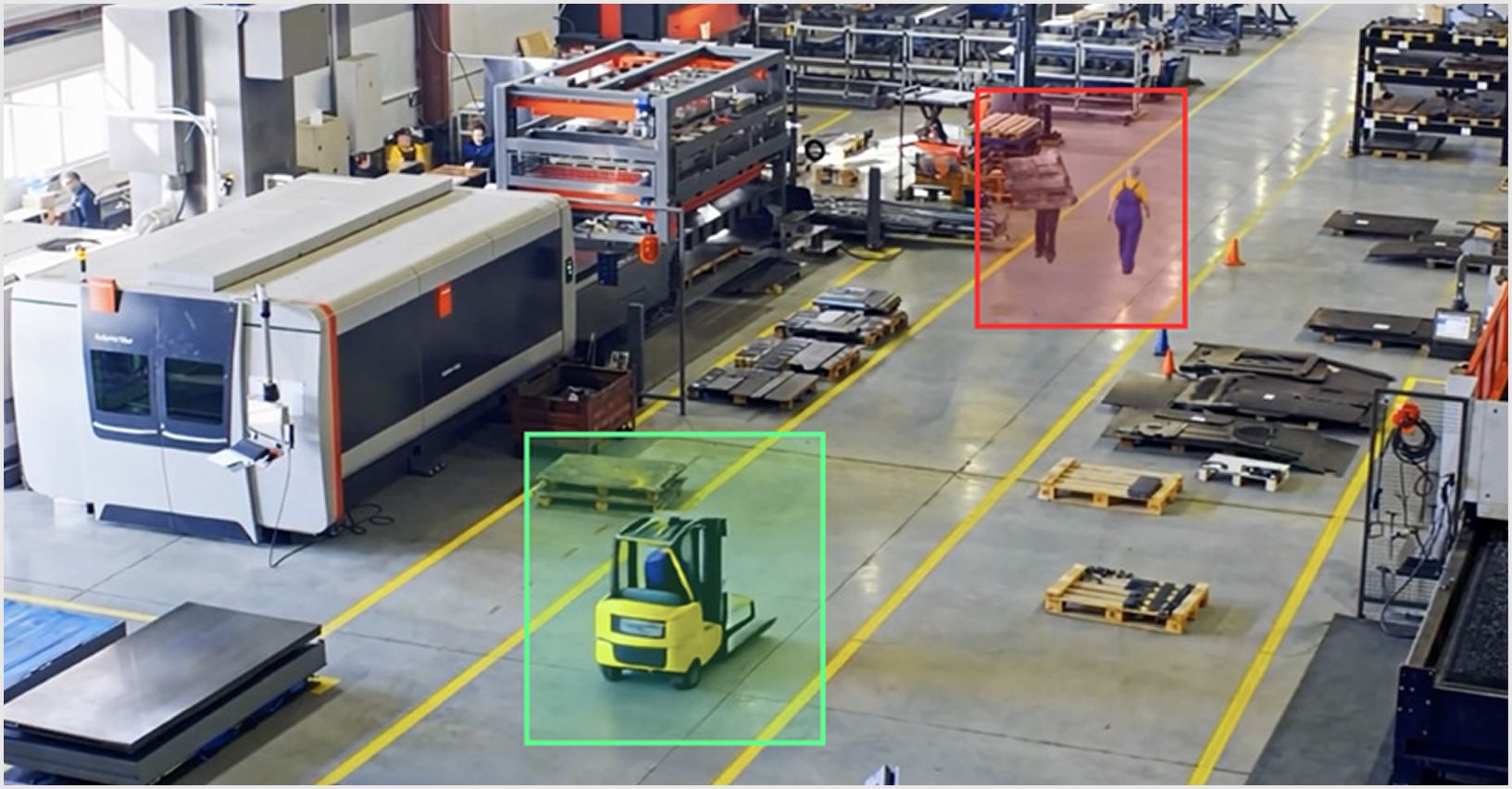

Monitoring of Specific Areas

Vehicle-only zones, fire hazard zones, restricted areas,

pedestrian-only zones, electrical hazard zones

pedestrian-only zones, electrical hazard zones

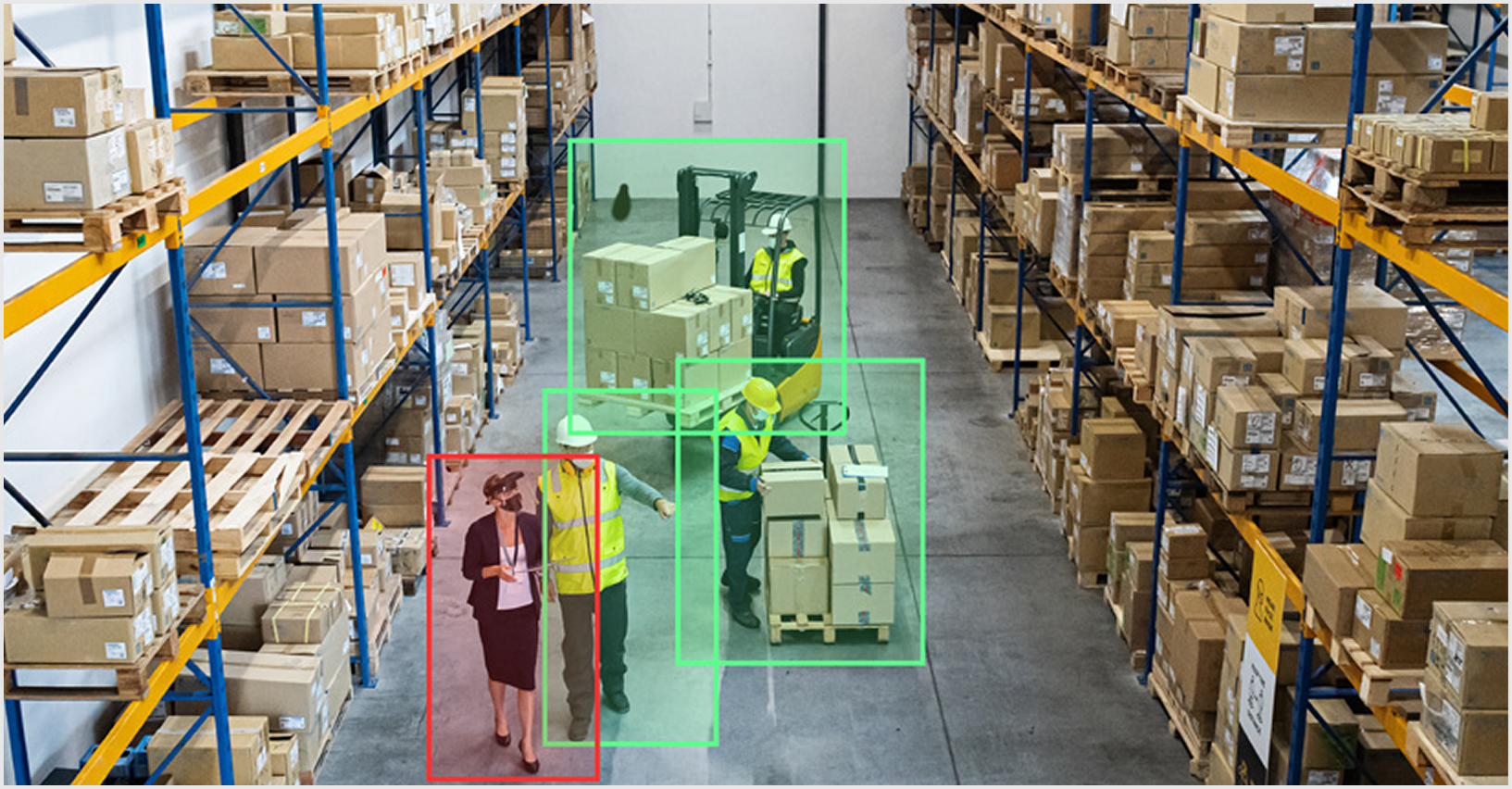

Heavy Equipment Collision Prevention

Worker proximity to forklift operations, worker presence in crane operating zones

Abnormal Situation Detection

Obstacles on sidewalks, obstacles on roadways

FAQ

Can it integrate with our existing CCTV

and video systems?

and video systems?

Yes, our industrial safety solution is compatible with a wide range of CCTV equipment and video management systems.

It supports both edge-based and centralized setups, making it easy to integrate into your existing infrastructure.

It supports both edge-based and centralized setups, making it easy to integrate into your existing infrastructure.

How accurate is the detection?

It’s designed to maintain high detection accuracy even in dynamic environments, adapting to changes in lighting, camera angles, and field conditions.

How is it different from traditional video

monitoring systems?

monitoring systems?

Powered by a Vision-Language Model (VLM), the system understands not just objects,

but the full context of actions and situations—without any prior training.

but the full context of actions and situations—without any prior training.

What kinds of risks can it detect?

It detects over 50 types of safety risks, including PPE violations, unauthorized access, slips, trips, and more

—providing comprehensive coverage of unexpected hazards. It also autonomously detects unusual or evolving risk patterns

beyond predefined rules—enabled by generative AI.

—providing comprehensive coverage of unexpected hazards. It also autonomously detects unusual or evolving risk patterns

beyond predefined rules—enabled by generative AI.

How long does deployment take?

Traditional computer vision (CV) models often require time-consuming data collection, labeling, and training—taking weeks or even months to deploy.

In contrast, Nota AI’s industrial safety solution is powered by a pre-trained Vision-Language Model (VLM), enabling rapid deployment in just 2–3 weeks

without the need for additional training.

In contrast, Nota AI’s industrial safety solution is powered by a pre-trained Vision-Language Model (VLM), enabling rapid deployment in just 2–3 weeks

without the need for additional training.